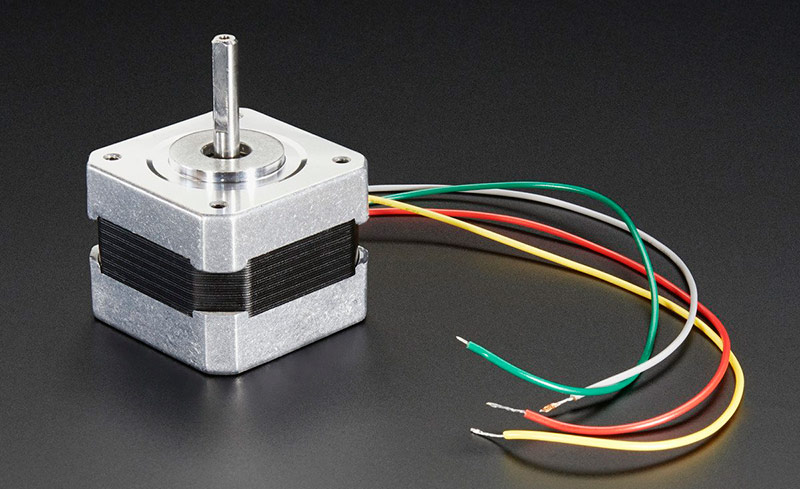

Stepper Motors have revolutionized machinery in today’s world. These motors are mostly used in 3D printers, CNC machines, Robotics etc. Stepper motor is nothing but a DC motor that moves in steps and each step can be controlled with precision. Therefore stepper Motors have high accuracy compared to other Motors also they have high torque which can handle heavy loads making it an ideal choice for machinery. Apart from this, these motors don’t have any feedback mechanism like Servo motor and operates in open loop condition.

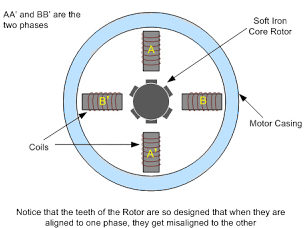

CONSTRUCTION OF STEPPER MOTOR:

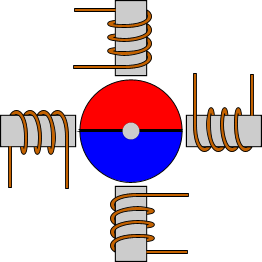

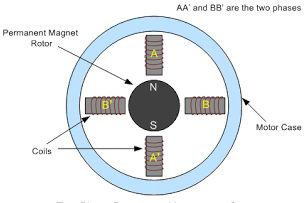

Stepper motor construction is quite similar to DC motor. It also has a permanent magnet as Rotor. Rotor will be in the center and will rotate when force is acts on it. This rotor is surrounded by a number of stator which is wound by magnetic coil all over it. Stator will be placed as close as possible to rotor so that magnetic fields in stators can influence rotor’s movement. To control the stepper motor each stator will be powered one by one alternatively. In this case the stator will magnetize and act as an electromagnetic pole exerting repulsive force on the rotor and pushes it to move one step. Alternative magnetizing and demagnetizing of stators will move the rotor step by step and enable it to rotate with great control.

Based on stator, it can be classified into two types. They are Unipolar and Bipolar stepper motors.

UNIPOLAR STEPPER MOTOR:

In a Unipolar motor the each stator winding has center tap setup which will connect to Vcc or Ground. In this setup current only flows to half of the winding at a time. The current either flows into or out of Center tap terminal based on what is connected to Vcc or GND. When current through the winding, stator will act as magnetic poles. Here allowing current through one half of winding will make the stator a North pole while current through other half will induce South pole. This makes the motor easy to control and operate in both clockwise and anticlockwise directions. A simple transistor at both ends of winding will suffice to run this type of stepper motor in both directions.

Despite the advantages Unipolar motor has less torque and cannot handle bulky load. Also since only one half of coil winding will be active at a time stator coil will be more resulting in increasing coil resistance.

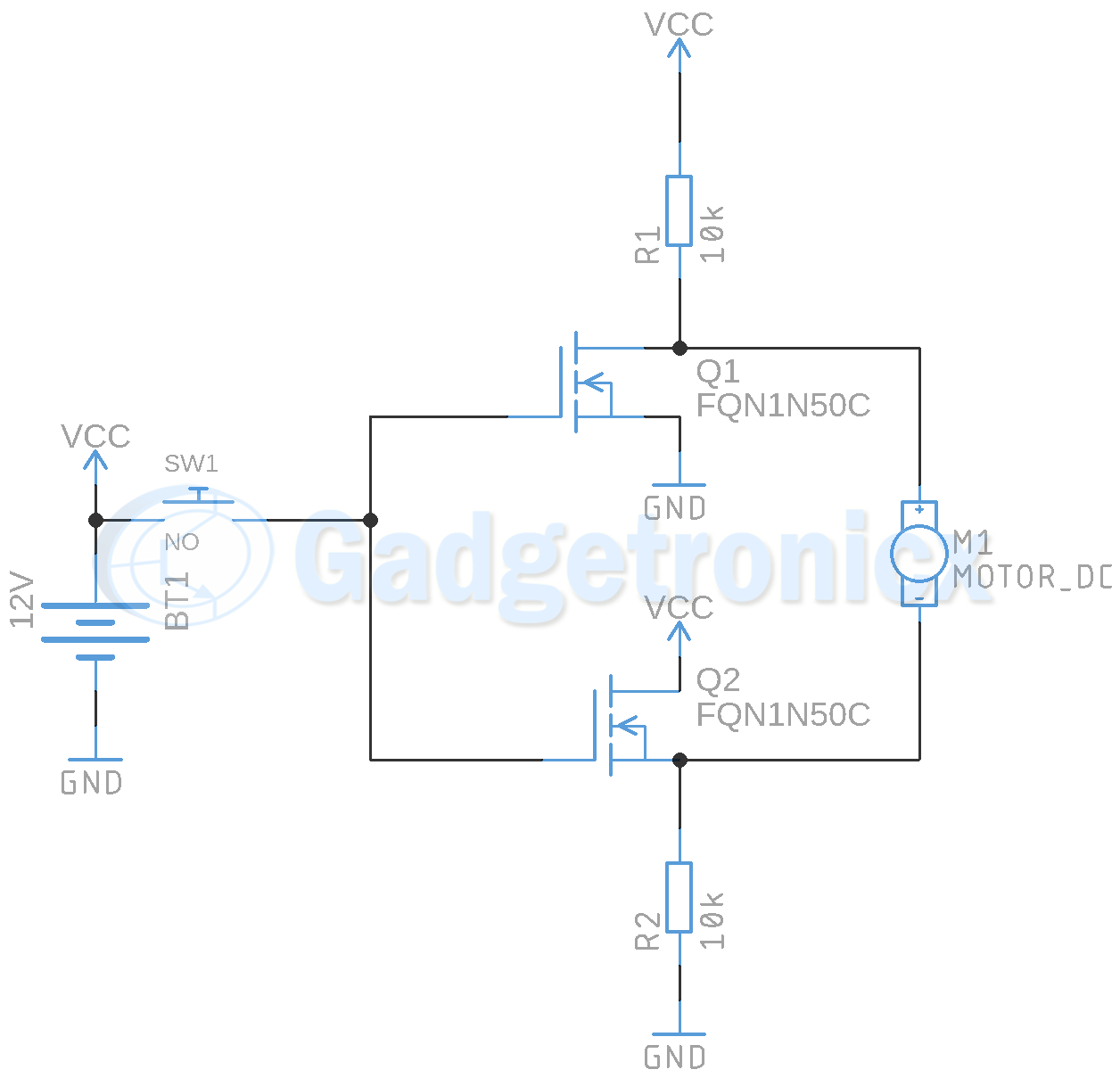

BIPOLAR STEPPER MOTOR:

On the contrary to Unipolar motors, stator winding of Bipolar motors don’t have a center tap connection hence current will flow through the entire coil. You can force the current through the coil by applying Vcc at one terminal while connecting other terminal to ground. The current flow in one direction will make the stator North pole while current flow in opposite direction will make it south pole. Unlike Unipolar motors, Bipolar motor needs special arrangements like H-bridge to operate them in both the directions. Bipolar motors have high torque and can deal bulky loads. But driving this motor demands special circuits which can increase the cost involved.

Stepper motors can be classified into different types based on it’s construction as well. We will see that later in this tutorial for better understanding.

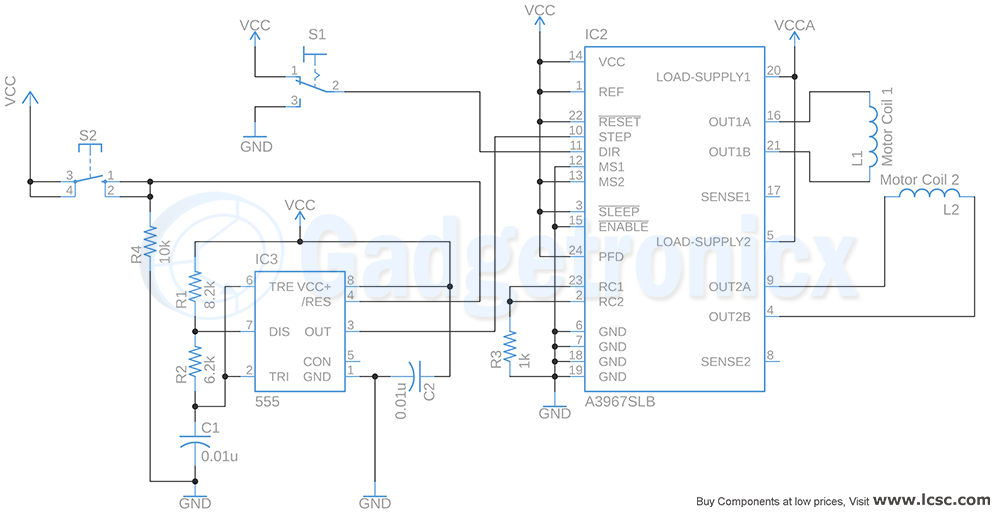

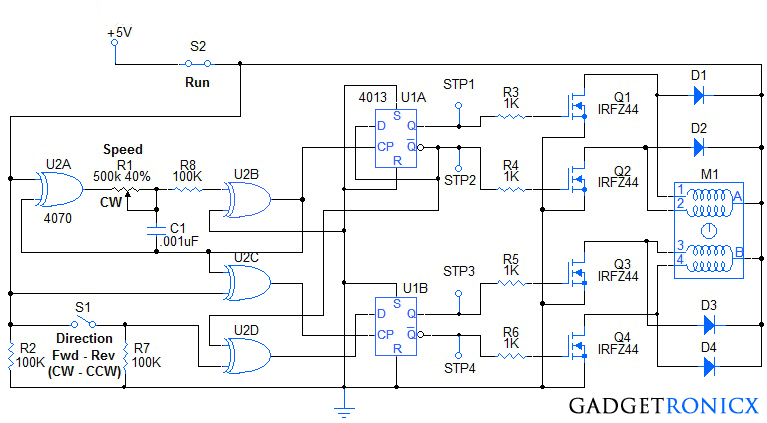

DRIVING A STEPPER MOTOR:

Stepper motors require special circuits to drive them because of their complex construction. There are many ways to drive a stepper motor. In this tutorial we are going to look at the most common ways of driving motors. For the purpose of explanation we will consider a four phase stepper motor.

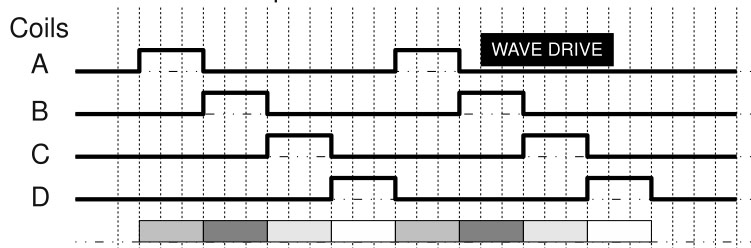

SINGLE EXCITATION MODE:

This is the most basic way of driving a stepper motor and it’s not used much but still worth knowing to understand the driving of stepper motor. In this method each phase or stator next to each other will be activated one by one alternatively using a special circuit. This magnetizes and demagnetizes the stator resulting in movement of rotor one step at a time.

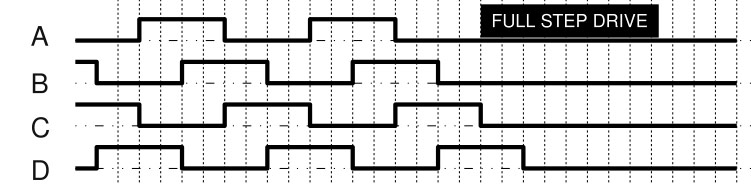

FULL STEP DRIVE:

In this method instead of activating stators one at a time two stators are activated with a short time period between them. In this mode any two stators will be active. This means first stator turns ON and second stator will be ON after a short interval while the first stator is still ON. This method results in high torque and enables the motor to drive high load.

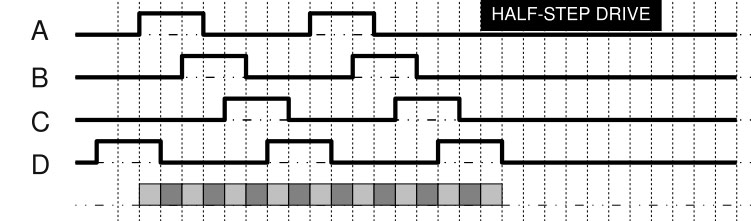

HALF STEP DRIVE:

This method is quite similar to Full step drive. Here two stators placed next to each other will be activated first and the third stator will be activated next; these two stators get deactivated. This cycle of activating two stators first and then one stator repeats to drive the stepper motor. This method results in increased resolution of motor while reducing the torque.

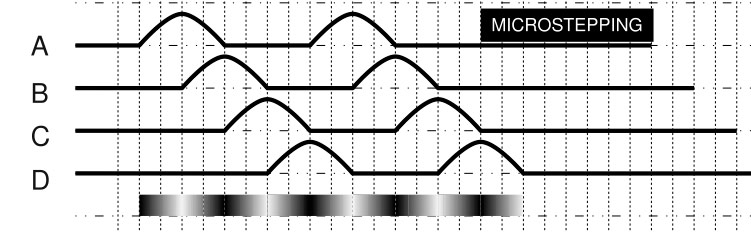

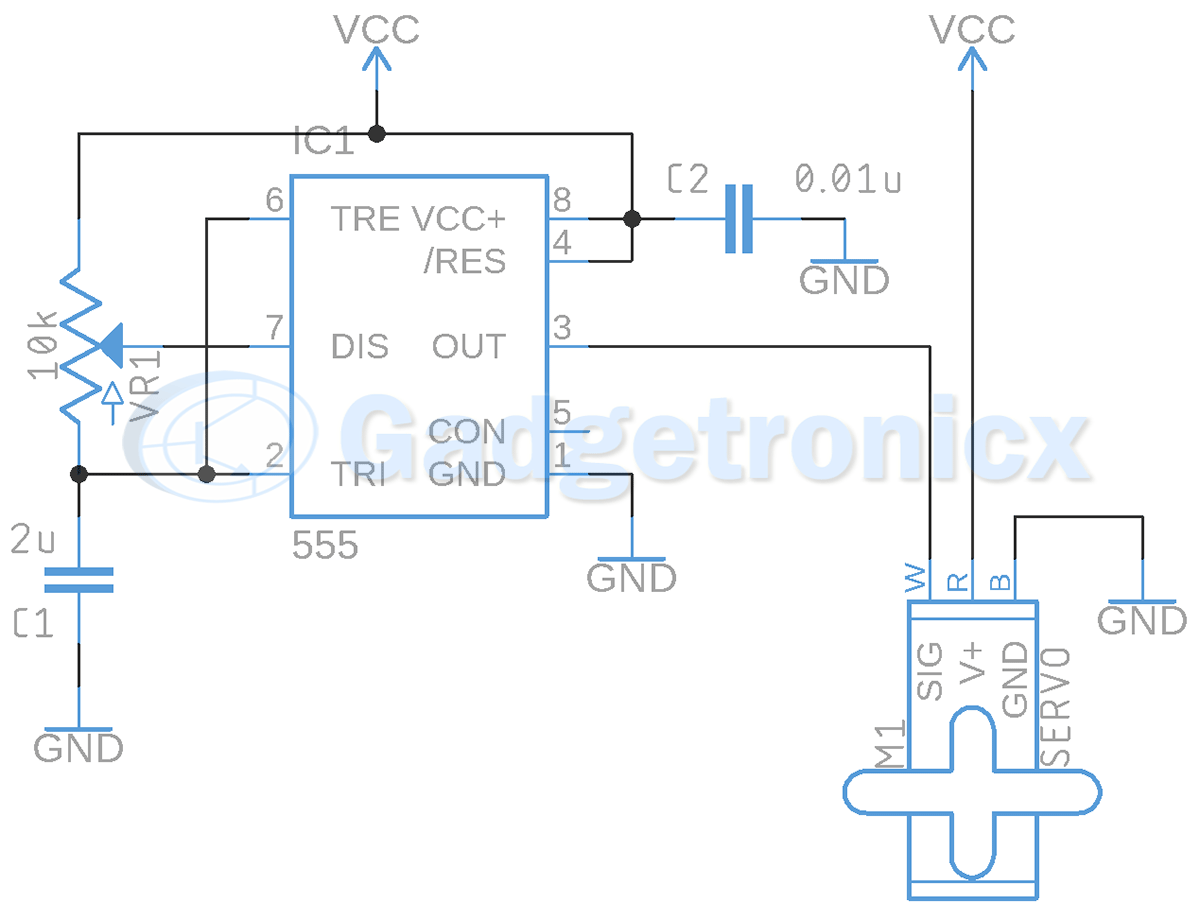

MICRO STEPPING:

This is the most commonly used driving method because of its accuracy. The driver circuit supplies variable step current to stator coils in the form of a sinusoidal waveform. These tiny step current smoothly enhance the accuracy of each step greatly. This method is widely used since it provides great accuracy and reduces operating noise to a large extent.

TYPES OF STEPPER MOTOR BASED ON CONSTRUCTION:

There are different types of stepper motor which varies with its complexity in construction and working. In this tutorial we will see some of the basic types and it’s construction.

PERMANENT MAGNET STEPPER MOTOR:

In this motor a permanent magnet is used as Rotor and electromagnetic stators around it. This is the motor we saw in above examples. Here the stator will be magnetized and demagnetized to move the rotor and set the motor to rotation.

VARIABLE RELUCTANCE STEPPER MOTOR:

This motor is built using Ferromagnetic rotor and Electromagnetic stator with coil winding to magnetize them. Here the rotor will have multiple projections also called as teeth which will act like magnetic poles. This stepper motor works based on Magnetic reluctance, hence got its name. When current passes through stator pole, it will magnetize and pulls the rotor’s projecting poles in a way the distance between them is minimum and in full alignment.The driver circuit will continue to magnetize stators setting the rotor into rotation.

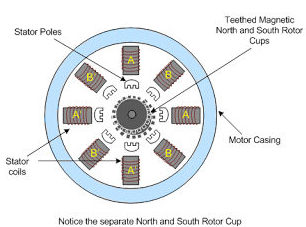

HYBRID SYNCHRONOUS STEPPER MOTOR:

This is a combination of above two motor permanent and variable reluctance stepper motor. This motor consists of permanent magnetic toothed rotor like the ones in permanent magnet stepper motor with set of north and south poles in it. Also just like variable reluctant motor the stators have teeth in it. Few teeth of stator will be aligned to teeth of rotor while others will not be aligned to each other. When stator is magnetized by supplying current to it, magnetic flux drives the rotor to move by one step. The presence of teeth in both stator and rotor changes the magnetic flux and drives the motor by steps as intended.

The Hybrid synchronous motor is most popular since it has high torque and resolution. Driving modes like half step can even increase the resolution of this motor. While full step or microstepping can be used to increase the torque, accuracy and smooth working. The hybrid motor is most popular because of the advantages it hold but comes with high cost due to its complex construction.

CHARACTERISTICS TO LOOK FOR IN STEPPER MOTOR:

These are some of the important characteristics you need to look for in a stepper motor.

- Resolution

- Rotating angle

- Operating voltage

- Torque

- Speed

Here you can find further detailed explanation of important characteristics of a stepper motor.

APPLICATIONS OF STEPPER MOTOR:

- Printers

- CNC machines

- 3D printers

- Laser and optics

- Industrial machinery

Hope this tutorial gave you great insights on What is Stepper motor, it’s Construction, Working and types. Check out other Electronic tutorials in our website. If you have any queries or feedback do post them in your comment box below. Subscribe to our newsletter and follow us through social media for more tutorials, circuits and projects.

Great Article. Thanks for sharing

Fahad,

Am glad that you found it useful.

The description is very nice, cover most of the hardware design and working.