Remote control Cars also known as RC cars are something every electronic hobbyists would love to build. But most of them didn’t know where to start and how to build it, some even got deceived by its complex looks. This article is focused to guide hobbyists to build their own homemade RC car with minimal components.

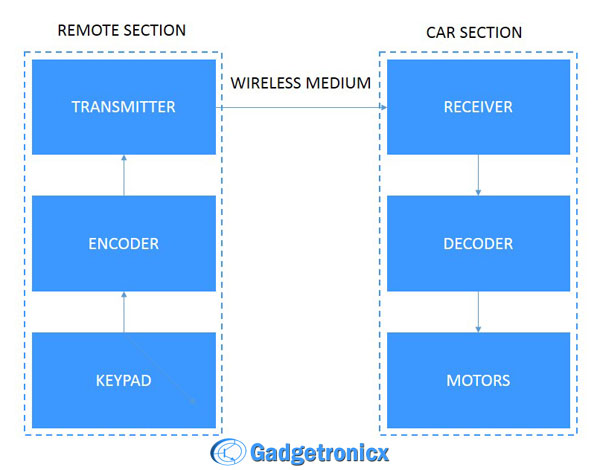

BLOCK DIAGRAM:

To build a RC car we need to make sure that these blocks are available. The above blocks are divided into two sections Remote and Car for the purpose of understanding. Starting from Keypad which controls the movement of the Car whereas Encoder and decoders are meant to encode and decode the movement signals for secured transmission. Also transmitter sends the movement signals through wireless medium and receiver fetches the signals for the destination.

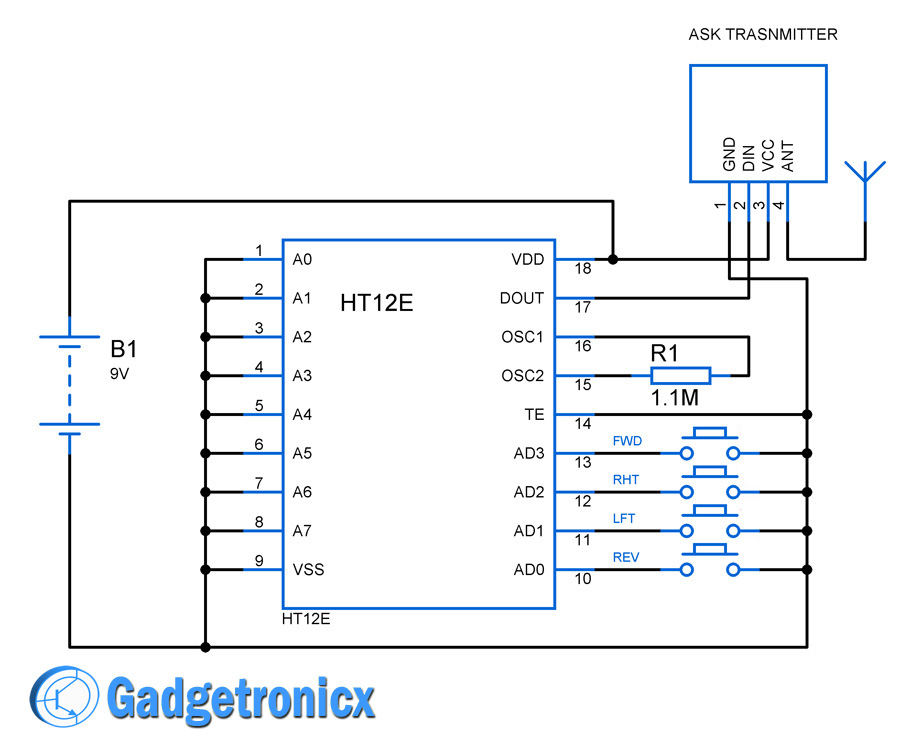

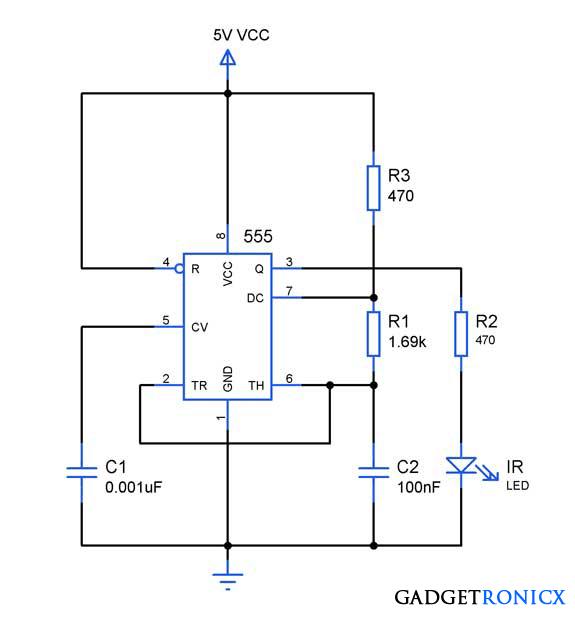

CIRCUIT DIAGRAM OF REMOTE CONTROL:

The above Remote control Circuit consists of three important components Keypad, Encoder IC HT12E and a RF Transmitter RF433 module.

KEYPAD: The Keypad for our remote is made up of four individual buttons which is wired to the data pins of the data pins AD0 to AD3 of the encoder IC. When these buttons are pressed it passes the movement signals to the encoder,

ENCODER HT12E: This encoder serves the purpose of encoding the movement signals fed by the individual buttons. The Data pins AD0 to AD3 is active low hence pressing the button closes the circuit and a logic 1 or high signal is fed to these pins. It also contains Address Pins A0 to A7 which allow us to try out different address combinations for secured transmission of data but make sure you use the same address combination in the receiving end (decoder). In the above circuit we did’t try out any address combinations hence all the pins are grounded. The Dout Pin gives the encoded output data. Read more about the Working of HT12E Encoder.

RF433 TX: This is a simple RF433 TX module which operates at frequency at 433MHz. The encoded data from the Encoder is fed into DIN pin of the TX and a simple antenna is attached to its 4th pin.

OSCILLATOR FREQUENCY: The Oscillator frequency of HT12E is 3.25Khz ( refer the oscillation frequency vs supply voltage graph in the datasheet ). This frequency is fixed using the resistor R1 ( 1.1M ) . Modifying this resistor value will alter the output frequency.

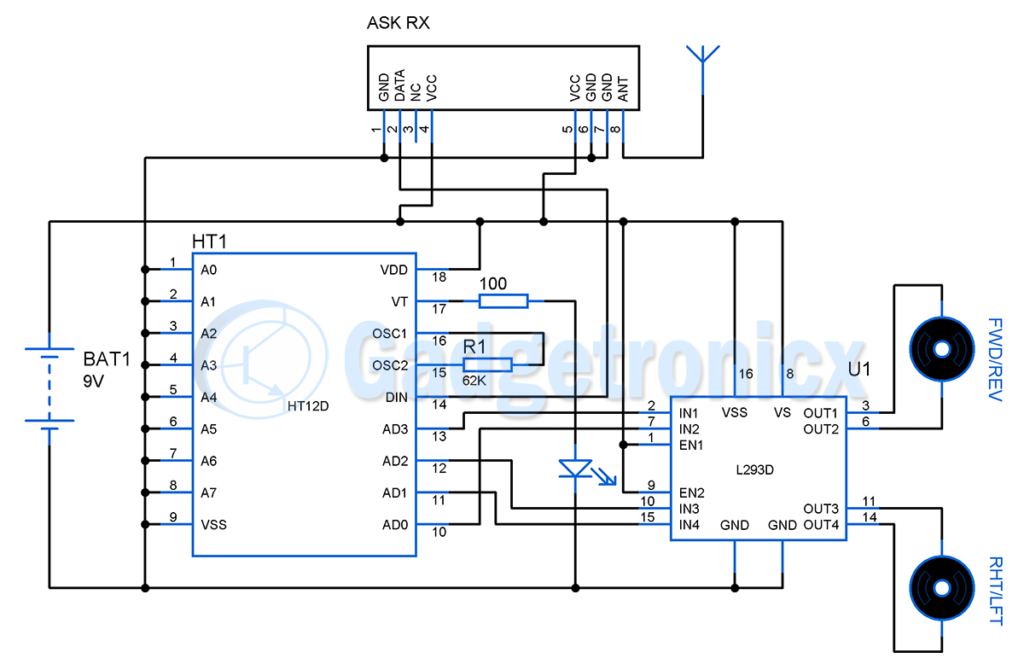

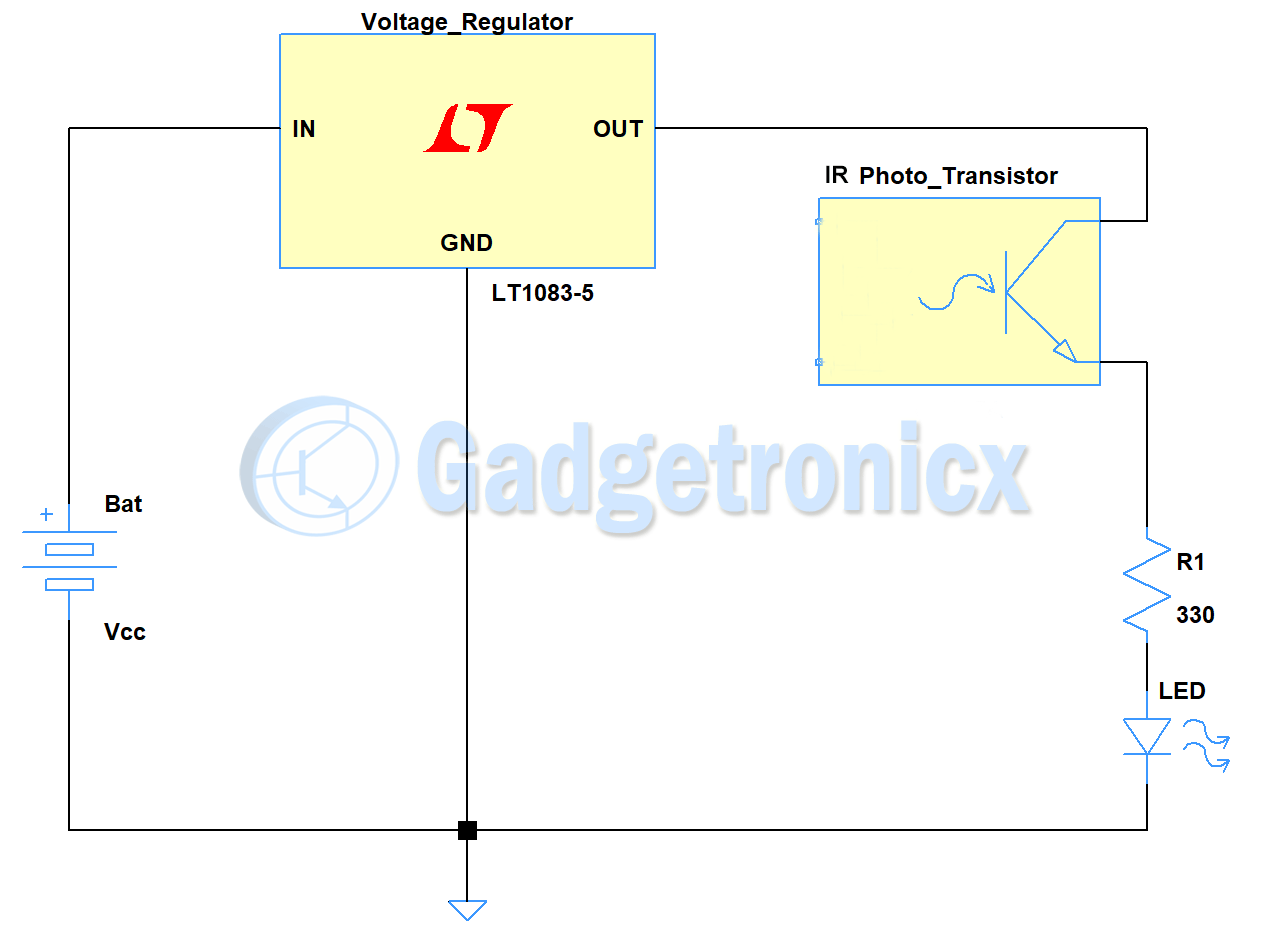

CIRCUIT DIAGRAM OF REMOTE CAR:

RF433 RX: This a simple RF433 RX module which operates at 433MHz. The received encoded data signals is received through the antenna and the signal is obtained from DATA pin to feed the decoder.

HT12D DECODER: The encoded signals from the RX module is fed into the DIN pin of the decoder. The signal is then decoded by the decoder, remember to use the same address combination used in the encoder if any otherwise the movement signals will be interpreted incorrectly. The decoder also consists of VT pin which serves as a identification if any RF link is established, LED was connected to this pin for identification.

OSCILLATION FREQUENCY: For successful reception of incoming signal and decode them, the HT12D oscillation frequency should be 50 times the encoder oscillation frequency. In our case HT12E oscillation frequency is 3.25Khz, hence our decoder oscillation frequency should be 162.5Khz. Fixing the value of R1 as 62K does this job ( refer the oscillation frequency vs supply voltage graph in the datasheet ).

L293D: This IC serves as a Bidirectional motor driver. It is highly impossible to drive heavy loads such as motors using decoder IC hence we have used a dedicated L293D IC for this purpose. Read more about the Working of L293D.

MOTORS: Two simple DC motors are used for the movement of RC Car. A motor for moving the Car forward and backwards whereas the other one is used to steer the car left and right.

MOVEMENT MECHANISM OF RC CAR:

We are done with the Remote control and the circuits which is about to be placed inside the car. Now next important thing is provide mechanism to move our RC car front and back. Fix a gear to the motor and to the rail which connects the rear wheels. Fix the motor close to the gear in the rail so that when motor makes a movement the car moves forward. Likewise when the motor rotates in the opposite direction the car should move backwards.

STEERING MECHANISM OF CAR:

Steering mechanism is bit tricky than the movement mechanism since it requires bit of mechanics. There are several Steering mechanisms used in building RC cars but here i prefer to use “Rack and Pinion” arrangement to steer the car in our desired direction.

The above animation shows the working of Rack and pinion steering mechanism. Here the pinion gear will be attached to our front motor which is responsible for Right/left steering. So when this motor moves in clockwise direction the car turn left and vice versa. See the working this gear arrangement in this video.

PARTS NEEDED:

- RF433 MHz TX and RX

- Encoder HT12E and Decoder HT12D

- L293D – 1

- Motors – 2

- Wheels – 4

- Resistors – As required

- LED

Hope this project was informative to you. Check out other Electronic projects in our website. If you have any feedback or comments about this project do leave them in the below comments section.

Hi Frank

Can give me the RF433 TX and RX Circuite

I want to make it myself …. Please

Master,

Its a ready made module and commonly available for buying. I don’t have schematic of this part.

Can you suggest me where to connect led in transmitter

Can u suggest me where to connect led in transmitter ckt so tat I will be able to know whether transmitter ckt is working properly or not

Can u suggest me where to connect led in transmitter ckt

Ayush,

Encoder IC HT12E doesn’t have dedicated pins to add up LED’s to check its working so you cannot do that. You can check its working only from the receiver end decoder where you have the facility to add LED and check its working. However an idea to check the transmitter working will be connecting the HT12E Dout pin to a CRO and observe the data signals. Hope this helps

I tried to make Remote control Car from your site’s design but I got some problems ,can you help me to complete this project..?

Dipanjan,

Please narrate your problem.

In decoder IC section, across oscillator terminal, when I touches the two terminal of resistor 1.1M ,it activities the VT terminal & LED grows up lighting, otherwise it doesn’t work.

The problem you are facing might be due to improper grounding i guess. So check the connections are hooked tight also take a glance at the antenna. Next possibility is a frequency mismatch so try replacing the 1.1 M resistor with 82K resistor in the decoder part. Try these things and let me know the outcome.

Thanks for useful advice, its working.

Dipanjan,

Glad it helped, keep building.

Frank,

This is a great write up. Thanks for putting this together. I got all of the elements connected and to the point that I know the wireless is working, I can press one of four buttons and one of the motors spins. However, it does not stop spinning. Each button will spin it’s respective motor one way or the other. Is there something that I have missed or a trick that you are aware of to get the motor to stop spinning?

Thanks

Perry

Perry Day,

Sounds like you got it right, Motor wheel keeps spinning? that’s an interesting challenge! It means that the high logic is continuous in output of the decoder. try adding a pull down resistor at the output of the decoder also replace the 1.1M resistor with 82K to the pins OSC1 and OSC2 in the decoder. Let me know the outcome of these changes

Thank you very much….your article helped a lot

Harini,

Glad it helped, keep visiting.

Sir can we know how to write program on chip

Vishal,

Which chip you are talking about?

please give me the daigram 4gb or above gb,s usb for like a computer use without any ic.?

Haroon,

Can’t get your question, make it clear.

@Frank , Nice post……

Murugan,

Thank you, hope you find it useful