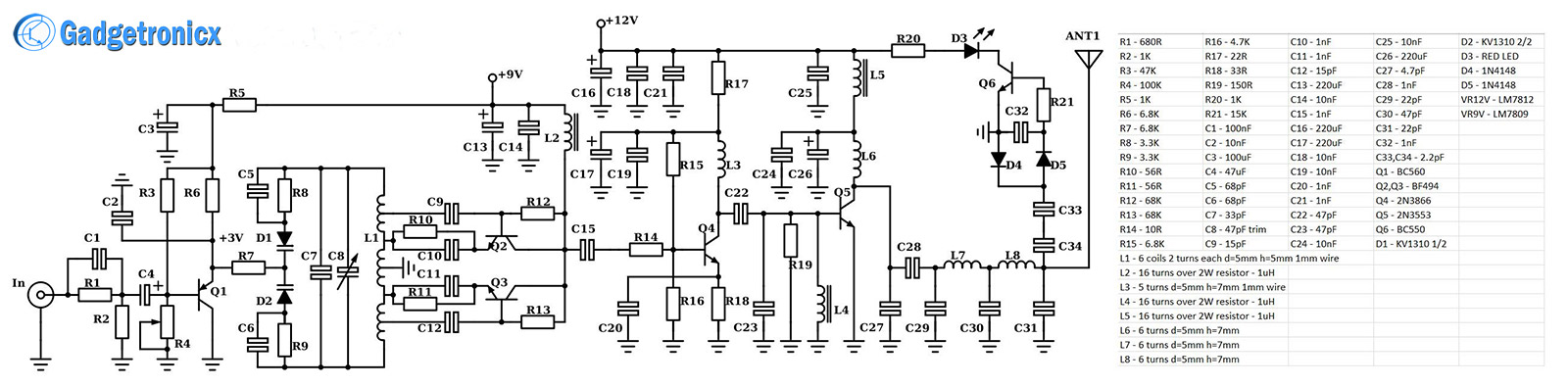

Metal detectors are fun to play with and I had always been fascinated to unearth things using that. Following that I have decided to design my own metal detector which offers better performance with some minimal components I could buy from my local radio store. Let’s get to the working explanation of this circuit.

WORKING OF METAL DETECTOR:

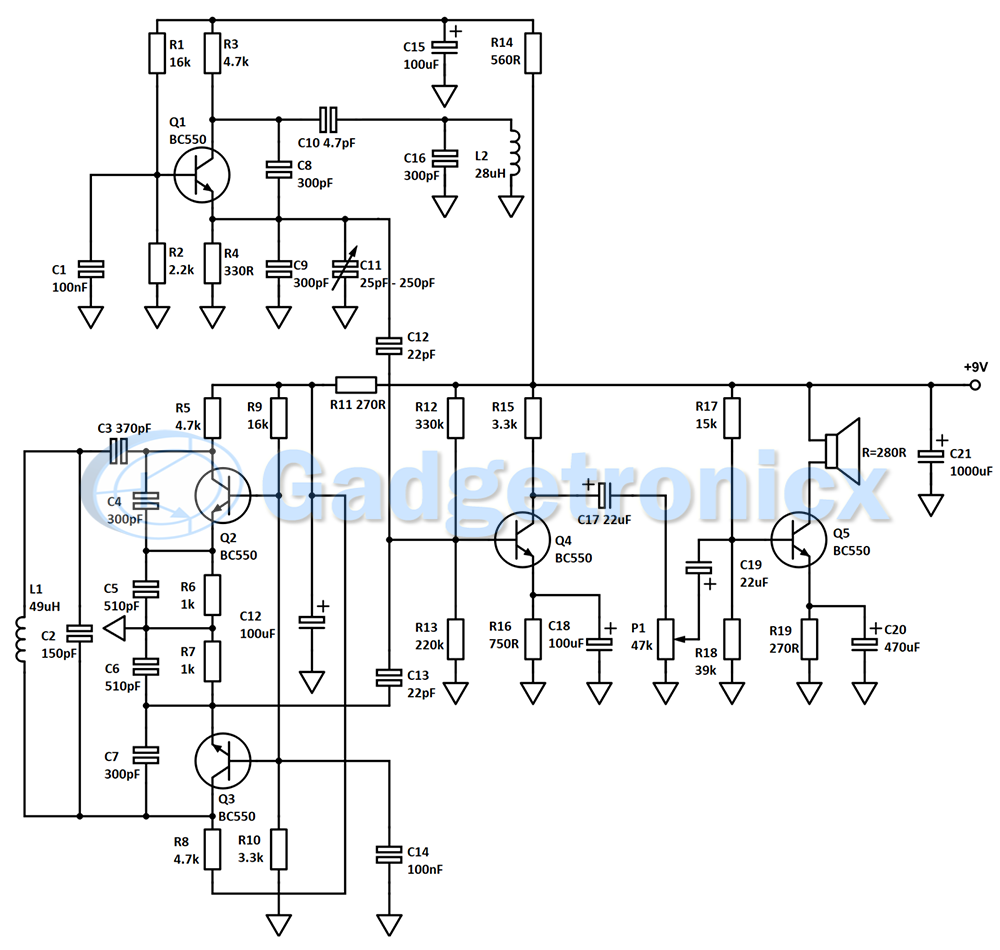

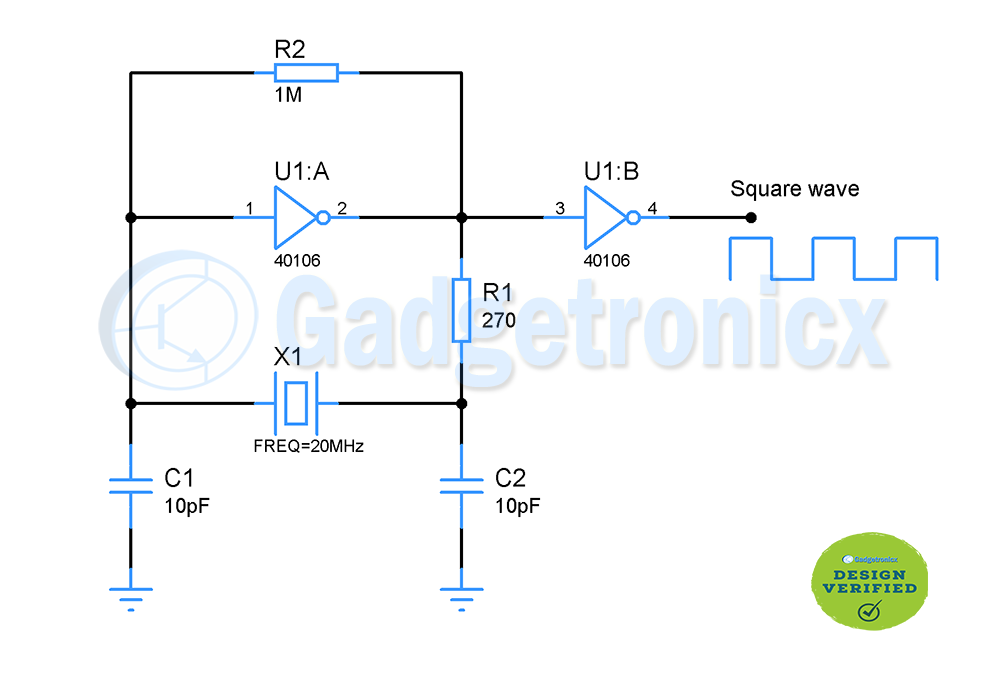

This is a Beat Frequency based metal detector, which works by using the lower heterodyne of two mixed signals coming from two separate oscillators. One oscillator generates a stable reference frequency, while the other oscillator works as a VFO (Variable Frequency Oscillator). Typically, the two oscillators are in sync, and there is no heterodyne generation by their output mix. While the reference oscillator keeps the frequency stable, the VFO changes its frequency in the presence of a metal object.

The L2 coil acts as a highly inductive antenna, which according to its proximity to metal objects, changes its inductance slightly. This causes the oscillator to experience a frequency shift. The two signals from the oscillators are combined by C12 and C13 and are fed to heterodyne amplifier. The heterodyne amp has no high frequency response and cancels out the high frequency component. It only amplifies the subtraction and sum of the frequency difference between the two oscillators. This low frequency heterodyne then goes to a power amplifier, which drives the speaker for an audible detection of the presence of metal.

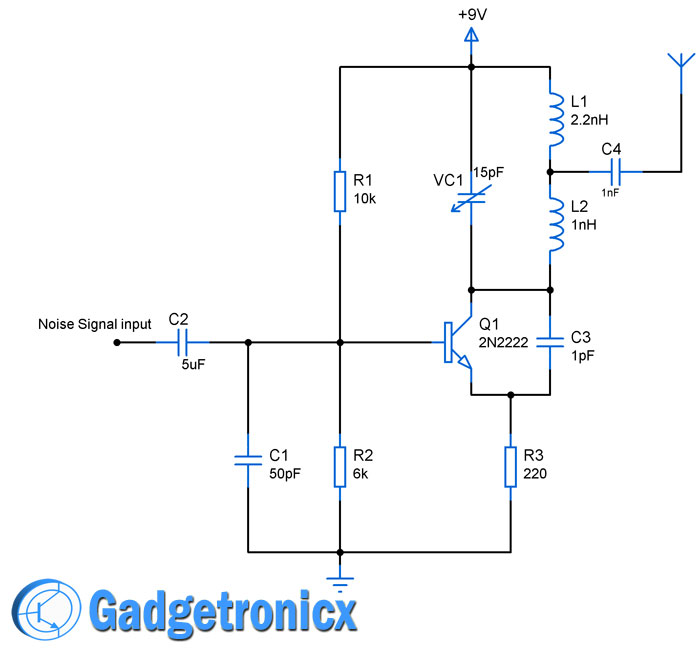

FIRST STAGE:

The first stage of the BFO metal detector, revolves around the transistor Q1. This is the reference oscillator, and is based on a Clapp Oscillator. The variable capacitor C11 is there to finely tune the frequency of oscillator, so that both the reference oscillator and the VFO are in sync and there is no heterodyne production at the output. You can change the reference frequency from 1.44MHz to 1.62MHz via C11 to match the VFO frequency. The output of this stage is from C12.

SECOND STAGE:

The second stage of the detector is a VFO oscillator. The VFO oscillator is designed in such way, that it actually uses two transistors Q2&Q3 , in order to create a more powerful EM field around the search coil. This increases the sensitivity of the metal detector dramatically, but increases the complexity somewhat. The L1/C2 form the LC tank circuit, which also has a center frequency close to that of the reference oscillator. The output of this stage is from C13.

THIRD STAGE:

The next stage is the heterodyne mixer and amplifier. The two outputs from both oscillators (C12,C13) are mixed at the base of Q3. I chose the value of these two capacitors deliberately to be so low. This is because when two oscillators work at near frequencies, a common connection between them may cause a “pulling” between the two oscillators. This will make their frequencies and phases match, which is undesirable.

The Q3 amplifier suppresses the HF component left in the mixed signal and amplifies the lower frequency heterodyne left from the mix. The stage must have a very low frequency response. The capacitor selection is in such a way as to not cause a low frequency roll off and decrease response. The output is taken from the collector of the transistor and fed to a potentiometer to allow the user to manually vary the sensitivity of the detector.

FINAL STAGE:

The last stage of the metal detector is just a common emitter amplifier. This further increases the level of the signal to drive a high impedance speaker and allow the user to hear the beats in the presence of a metal object. This stage is not critical and you can replace it with an op amp amplifier as well. But for the sake of simplicity, I have chosen to design it this way.

PRACTICAL CONSIDERATIONS:

- To ensure the reference oscillator stability, it is best to build it separately (on a different PCB) from the VFO. This will minimize any external influence to the reference oscillator and also cancel out the “pulling” between the two oscillators.

- I strongly recommend to keep the decoupling circuits R11/C12 and R14/C15. Since the 9V battery used to power the detector has considerably high internal resistance, these two oscillators may pull each other from coupling through the supply rail.

- You can make the search coil by winding 5 turns of 0.8mm wire on a rectangular frame measuring 70cm in length and 40cm in width.

- IT IS VERY IMPORTANT to shield the search coil with aluminum foil connected to the common ground rail of the circuit via a copper wire. This will minimize capacitive coupling between the coil and the soil. This inturn may lead to false detection, without the presence of a metal object in the vicinity of the coil.

- The way to properly shield the coil is to wrap the finished coil in aluminum foil. Then wrap the foil itself with an extra layer of non enameled copper wire. This should be connected close to the negative terminal of the battery.

- When designing the construction of the metal detector it is best to keep the search coil close to the VFO. Also shield the VFO in a metal case just above the search coil.

- Keep the reference oscillator separate from the VFO in a different shielded metal box right below the handle of detector.

- You may want to add a switch or a button or change the last stage with an op amp. The speaker driver stage is working in class A, which drains constant amounts of current even when idling, and will probably drain the 9V battery quickly.

- Alternative to the phone speaker, you can use headphones, which have a considerably higher sensitivity and bandwidth. In this case an op amp and DC decoupling is mandatory.

Hello, can I get your e-mail address?

Hi Caylan, Use this page to https://www.gadgetronicx.com/contact-us/ write to us .